Yamunanagar, Haryana – Once the thriving hub of India’s plywood production, Yamunanagar’s plywood industry is now grappling with a severe survival crisis, triggered by a persistent shortage of poplar and eucalyptus wood — its primary raw materials.

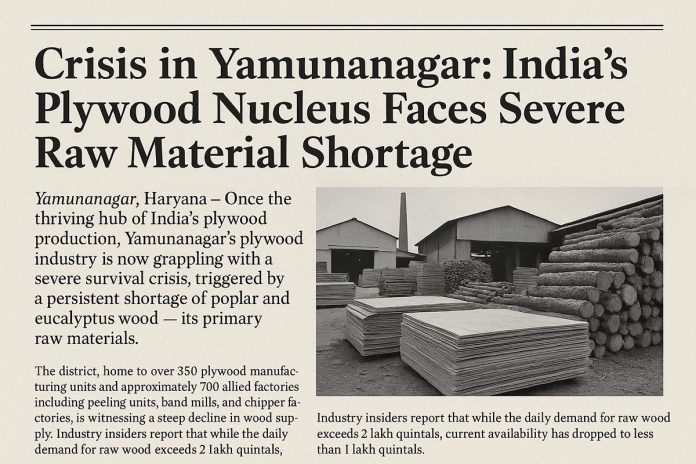

The district, home to over 350 plywood manufacturing units and approximately 700 allied factories including peeling units, band mills, and chipper factories, is witnessing a steep decline in wood supply. Industry insiders report that while the daily demand for raw wood exceeds 2 lakh quintals, current availability has dropped to less than 1 lakh quintals.

Roots of the Shortage: Overexpansion and Market Dynamics

The supply crunch stems from policy shifts and market dynamics dating back to 2016, when the Haryana government opened new licensing opportunities for plywood units following a survey on poplar and eucalyptus wood availability. Encouraged by then-plummeting wood prices — with poplar rates falling from ₹1,200 to ₹400 per quintal — farmer associations such as the Haryana Poplar-Safeda Utpadak Sangrash Samiti advocated for more manufacturing units, believing it would stabilize prices and benefit local cultivators.

The resulting influx of factories in Yamunanagar drove up demand, subsequently boosting prices. Today, poplar rates have rebounded, ranging between ₹1,300 and ₹1,500 per quintal. While this shift has helped farmers, it has severely strained manufacturers who now face raw material scarcity and rising input costs.

Shifting Supply Chains: The Role of Uttar Pradesh and Uttarakhand

Traditionally, a significant portion—over 50%—of Yamunanagar’s wood supply came from neighboring Uttar Pradesh. However, with the rapid establishment of plywood units in Uttar Pradesh and Uttarakhand, local farmers there are increasingly selling their produce within state borders, redirecting the supply away from Haryana’s industrial cluster.

This shift has intensified the crisis in Yamunanagar, which is no longer able to source enough wood to sustain daily production requirements. Since 2020, the supply from Uttar Pradesh has declined markedly, compounding the industry’s operational difficulties.

Industry Voices Demand Urgent Intervention

“We are operating under severe constraints,” said Anil Garg, Executive Member of the Haryana Plywood Manufacturing Association. “The industry is starved of essential raw materials. Without immediate intervention, hundreds of units could be at risk of closure.”

JK Bihani, President of the Association, has called for immediate policy support, including the abolition of the 1% market fee levied on wood purchases. “This industry is in a financial bind,” he stated. “Relief in taxes and fees is critical for our survival.”

What Lies Ahead

Yamunanagar’s plywood ecosystem plays a crucial role in both local employment and the broader Indian construction and furniture sectors. With thousands of workers and farmers dependent on this supply chain, the current situation poses a significant threat to regional economic stability.

Industry stakeholders are urging state and central governments to consider comprehensive policy reforms — including better wood plantation incentives, inter-state trade facilitation, and financial relief — to revive the industry and ensure its long-term sustainability.

For India’s plywood sector at large, Yamunanagar’s plight serves as a stark reminder: sustainable sourcing, balanced licensing, and proactive policy-making are critical for industrial resilience.